With major trade exhibitions just round the corner, sportswear giant Fila couldn’t roll out all its new season product samples because of the coronavirus pandemic. Many household brands like Fila have also been hit by the Covid-19 social distancing measures and travel restrictions that have physically separated shoe designers from the rest of the supply chain.

The disruption of the product development process can now be solved by using a SaaS platform developed by Chinese startup 4D ShoeTech. The newly released Ideation provides a collaborative workspace for designers, shoe brands, material suppliers and manufacturers to work together at any location to bring new products to market.

Using Ideation, Fila has managed to complete over 900 colorways and digital versions of all its samples within two weeks, enabling the company to launch a virtual display for the trade show.

The art of shoemaking involves very complicated techniques and a much longer timeframe is needed for product development compared to other fashion products. It takes over a year to bring a shoe design to the shelves, while apparels usually take 3–6 months. 4D ShoeTech can significantly accelerate the speed to market, slashing the time to 24 weeks instead of the industry average of 64 weeks.

But the global market for footwear is huge, valued at $365bn for 2020 and expected to exceed $530bn by 2027. As the largest shoemaker and consumer in the world, China alone produced 13.5bn pairs of shoes, almost 57% of the global total of 23.7bn pairs in 2018 and over fives times more than India ranked in second place.

It’s no wonder that 4D ShoeTech has managed to raise nearly RMB 100m in June in spite of the Covid economic downturn. The Series A1 funding round was led by CMC Capital was joined by Sequoia Capital China and existing investor Linear Capital.

New normal for product designers

Shoe brands rely on the skills and experience of designers who examine the shoe samples made by the factories before deciding if the prototypes are ready for mass production. During the Covid travel restrictions, the logistics services were disrupted and many companies resorted to sending photos of the samples to the designers for review at home. However, the designers were unable to get hold of the actual prototypes for testing before giving the go-ahead for mass production by the factories.

Ideation eliminates the need to send physical samples back and forth among the designers, shoe brands and factories. Designers can create the individual elements of a shoe including heels, soles and bottoms, and turn them into digital samples. The designs are not presented as static images. The lifelike 3D digital models display realistic details and precise specifications.

The company believes that its digital modules are indistinguishable from physical samples, creating “a true 4D effect,” a quality emphasized by the corporate name 4D ShoeTech. “Viewers can visually feel the full texture of the product,” the startup said in a recent news release.

Ideation can also be used to build a database from the data provided by material suppliers to enable them to showcase their products directly to the designers. After finishing the design and choosing materials, the designer can contact the suppliers to order the materials selected using a bill of material (BOM) generated by the platform.

The most intricate materials, ranging from fur, embroidery and embossed leather to metallic, glitter, iridescent and rhinestone, can be fully showcased by the 4D ShoeTech platform. The Ideation software can digitalize the shoe in-and-out showing the original design details, from the heels to the mold-making components including any embroidery, glitter, or tiling and pattern creations.

Ideation can also be used to create virtual showrooms to help shoe companies showcase their products to global buyers for direct purchase with just a few clicks.

To achieve such high quality results, the company has hired a team of experts who used to work for global picture rendering companies. "The customers are assured to get exactly what they see,” said 4D ShoeTech CEO and co-founder Lin Zisen.

Efficient and sustainable

The traditional shoe design process starts with concept sketching and 2D drawings on paper. The 3D molding is then created on computer and the physical samples or prototypes are made for review and product testing. The whole process has to be repeated even if a slight change is made. The traditional shoe development timeframe usually takes 64 weeks, with hundreds of prototypes created before the final approval is given for the mass production of one footwear product.

In one year, a footwear brand may plan to launch 1,000 shoe styles involving 4,000 colorways. The manufacturer may have to spend around RMB 10m just to create the physical samples, but only 20–30% of the 4,000 samples will be used for mass production.

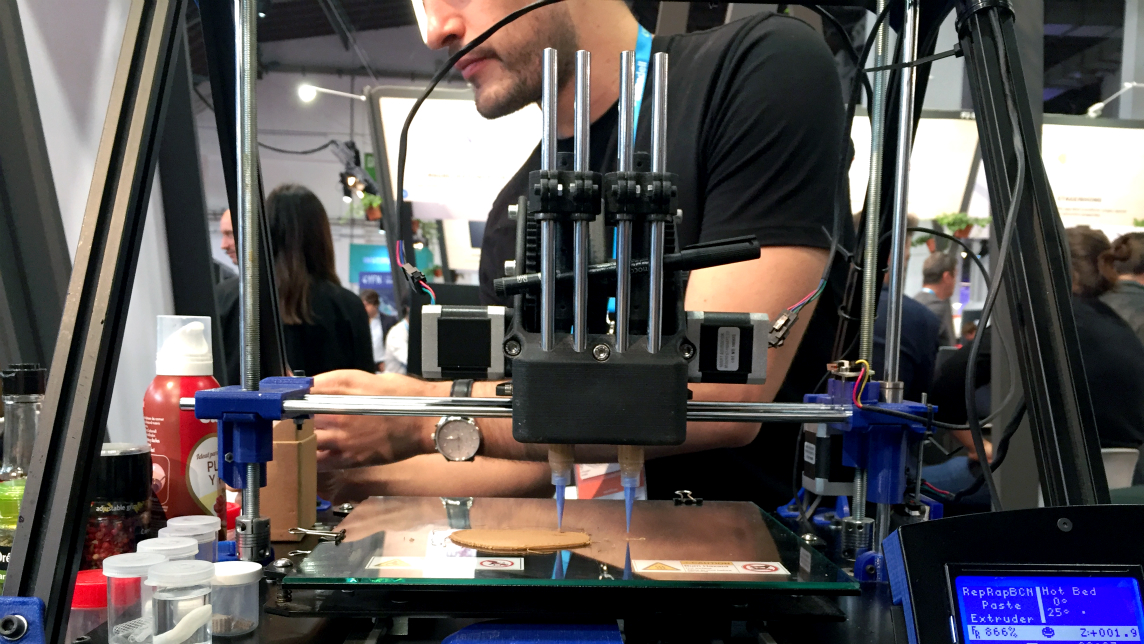

Only 300–400 physical samples need to be made using Ideation’s 4D modelling concept. The traditional mold-making technique is also replaced by 3D printing to make the shoe soles. As a result, product development costs can be cut by about 80%, a huge bonus for cash-strapped businesses that saw sales plummet during the Covid pandemic.

But 4D ShoeTech won’t stop here. The startup is already exploring new markets for its 3D modeling capabilities. In June, the company poached a whole team from Li & Fung, the world's leading consumer goods supply chain solutions provider. The new team will be responsible for the digital production of suitcases.

About 80% of its 160 employees are engaged in R&D. The company has invested in setting up R&D centers and business development teams in Guangzhou and Dongguan in China and Los Angeles in the US. 4D ShoeTech has also worked with 40 diverse clients across 11 countries including Walmart and Disney.