Backed by funding totaling over €7.5 million since 2014, Alternative Energy Innovations (AEInnova) is now ready to launch its game-changing energy harvesting system in Spain. Employing the "Seebeck effect" to generate electricity out of temperature differences, the AEInnova system improves energy efficiency and reduces the CO2 footprint of industries, as well as expands the concept of Industry 4.0 – all without complicated installations or expensive maintenance.

Their technology combines the latest advances in thermal energy generation with a sophisticated microelectronic system. AEInnova will soon be launching two types of energy harvesting systems, to be trialed in diverse sectors internationally, including at two Spanish oil companies, a European energy producer and an iron and steel company.

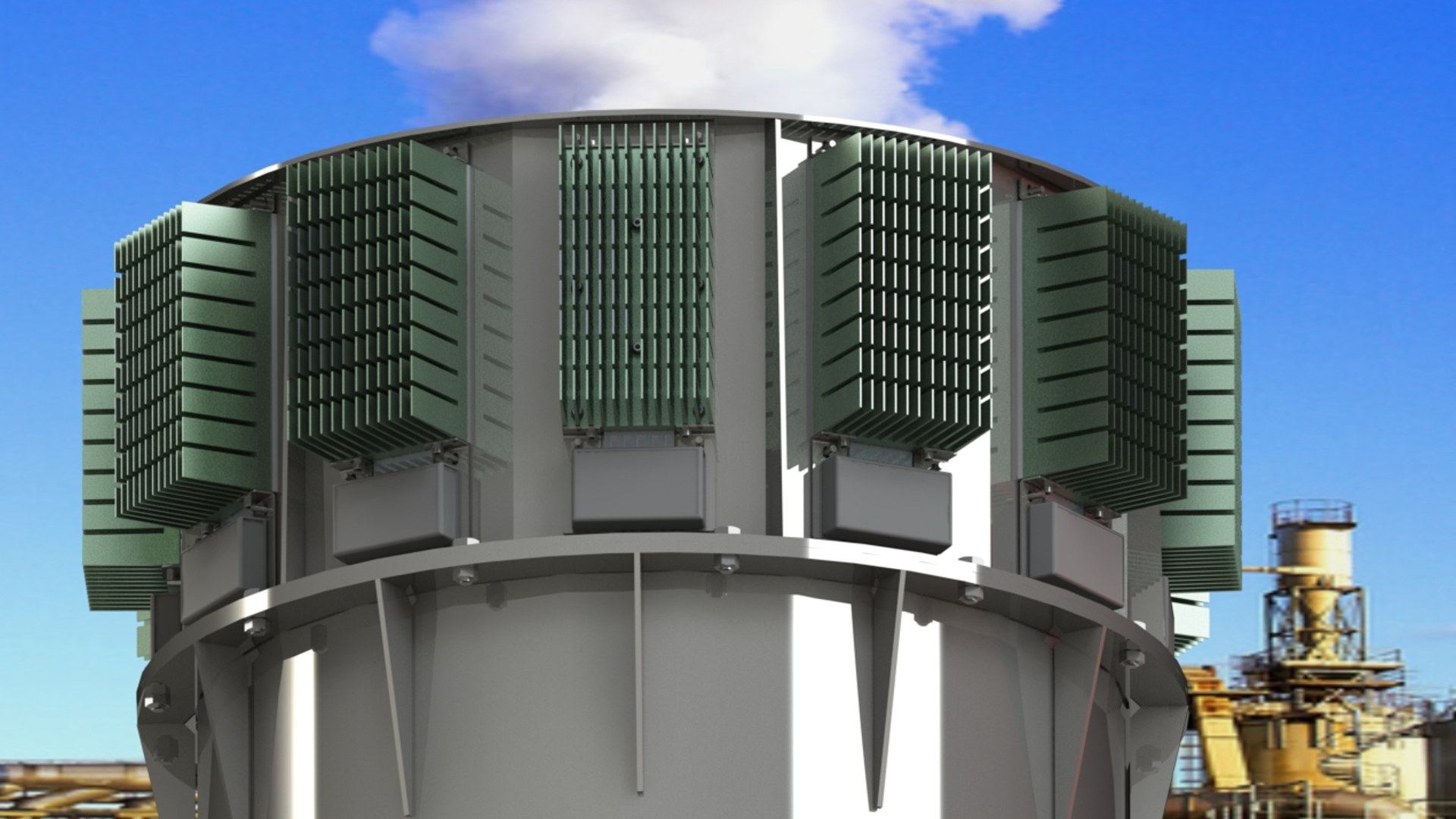

The first commercial product is INDU-EYE, ready for sale in 2Q19. It's the first autonomous, self-powered sensor and monitoring wireless device. The second product is the Waste Heat Recovery Unit (WHRU) that is being developed and tested in pilot projects in various industrial sectors.

The company is raising its Series A round of funding this year. Other focuses will be on developing the business in Europe, before expanding to the US and Canada where the first patents will be obtained within the next two years. The cleantech startup is also looking for local partners to develop new markets in Asia and the Middle East.

CompassList recently spoke to CEO David Comellas Vogel to find out more about his revolutionary energy company.

This interview was conducted in Spanish and translated by CompassList. It has been condensed and edited for clarity.

Q. How well positioned is AEInnova to make an impact?

A. We are in the right place, at the right time. The market is ready for our solutions. Energy efficiency is a real need for industry to reduce its energy costs and environmental impact, and it is also a social demand for environmental reasons. Digitalization in the industry is happening now. McKinsey estimates the potential market at US$30 trillion over the next 15 years and we have solutions to cover an important part of this demand.

What are AEInnova’s sales figures?

We are in the final development phase and hope to be in the market during 2Q19. We expect revenues of over €2 million in one year, with high growth within the next five years and expect more than €10 million in revenue in this period. We are conservative in our financial projections at this moment, but we are in conversations with two of the biggest European operators for a distribution agreement that could multiply our sales roadmap four-, fivefold.

How much have you invested? Are you planning any financing rounds soon?

We have seen over €3.5 million invested in our project, including €1.28 million from public and private grants such as the Repsol Foundation Entrepreneurs Fund. Recently, we became part of the LIFE+ program of the European Commission that funded €650,000 to develop Waste Heat Recovery (WHR) technology. We received €1.3 million of the total in private equity investment from angel investors, KIC Innoenergy and Banco Sabadell's BS10 fund.

In 2018, we closed a seed round of €750,000 with Banco Sabadell and will secure an additional €200,000 in January 2019 from them. At the end of 2019, we will start Series A capital raising to fund our growth.

What kind of clients are you targeting?

We are focusing on big industries with high energy consumption and waste heat losses. The target sectors are: oil and gas, chemicals, iron and steel, cement, energy, glass, paper, food, bricks and tiles.

We have successfully contacted decision-makers in our target industries and in the pre-sales plan. We have signed Letters of Intent to test the technology in more than 10 big international industries and some NDAs signed. We are working closely together with the biggest European energy producer and supplier to install a pilot in a coal-powered plant in 1Q19. We are also collaborating with the two biggest Spanish oil companies and one of the biggest European iron and steel companies to test the technology.

Do you have any competitors?

In heat recovery, we compete against the old-fashioned steam turbine that is the most common technology to recover heat and convert it again into electricity. But it is a huge and expensive technology, which is complicated to implement and needs a high level of maintenance. We can use our alternative installations where turbines are not suitable, or we can also complement it, for example at Siemens and Turboden.

In Wireless Sensor Networks (WSN), we compete against wired systems that are the most expensive, or the most common battery-powered wireless systems. We have the first battery-free self-powered solution on the market but other systems from Bentley-Nevada, Honeywell or Bosch are our competitors.

What is AEInnova’s business model?

We are committed to achieving a circular and local economy by reducing transport costs, environmental impact and enhancing production to the final users. The company's energy harvesting system uses the "Seebeck effect" process to generate electricity from temperature differences. This heat loss or waste heat has a high environmental impact due to inefficient industrial systems. AEInnova also uses big data, IoT and sophisticated microelectronic systems to improve energy efficiency and thus reduce the CO2 footprints of industry, without complicated installations or expensive maintenance.

We develop and sell the technology for various energy harvesting solutions. The production of the required energy harvesting system for each client is outsourced to local suppliers and integrators. This model will allow us to grow quickly with less CAPEX needs. We avoid all activities where we cannot add value, like production or distribution. Therefore, we prefer to outsource and work with partners to produce near the locations of our customers. This reduces industrial risks, costs and barriers, allowing us to generate local wealth and become part of critical markets like the US or Northern Europe.

What are the short-, medium- and long-term plans for the company?

In the very short term, we are focused on getting our first commercial product INDU-EYE, or Industrial Eye, ready for sale during 2Q19. It is the first autonomous and self-powered (by heat, of course) sensor and monitoring wireless device. We will concentrate on developing the European markets, but we also plan to expand to the US and Canada where we will obtain our first patent within the next two years. The Middle East and Asia are also in our focus, but probably via local partners.

We have been working on the internationalization plan with the Catalan Government called the SCALECAT program. We are also visiting potential customers in northern Germany and the US. We also have a partner who will deal with the Italian market because he knows the industry very well due to his senior position on the management board of one of the biggest European chemical companies.

Our Waste Heat Recovery Unit (WHRU) needs a little bit more development to be market fit. Therefore, we will work with some early adopters to test the prototypes in real industrial environments, supported partially by the LIFE+ grant. We will install six pilots to test and validate the technology during 2019.

How did you get the inspiration to create AEInnova and generate electricity from waste heat?

AEInnova is a spinoff from the microelectronics department of the Autonomous University of Barcelona to tackle climate change and improve environmental protection. Their knowledge in thermoelectric technology and microsensors in ultra-low power electronics was the starting point for the AEInnova solutions being developed now.

Industry is energy-intensive but is also very inefficient. On average, 70% of the energy used is wasted in the form of heat. In Europe, 700 terawatt hours (TWh) are lost with a high environmental impact in the production of that energy. The recovery of part of this wasted energy is a key target for the environmental policies drawn from COP 21 and COP 24 Climate Agreement in Katowice, Poland. Our technological proposal will help the industry to achieve its obligations where there are no other suitable or possible technologies.

AEInnova was founded in late 2014. What are your milestones and challenges to date?

After three years, the structure of the company has changed. Our founding team originally included experts in the field of microelectronics for space applications, microsensing and ultra-low power electronics and mechanical engineering to drive through our first thermoelectrical mechanical development.

Today, only three founders are still working full time on the project: Dr. Raúl Aragonés, Roger Malet and myself. Dr. Raúl Aragonés, the main founder and “father” of the idea, is the chairman and business development manager. Roger Malet is a friend of Raúl and company board member. He worked hard as an electronic engineer on our first patent.

I joined as the company's first investor and Aragonés asked me to collaborate in creating and developing the business model, finance and sales plans. Eventually, I was appointed as CEO. The rest of our team are professional staff hired during the last year. The most important thing is that we have a well-balanced team, with expertise in the technological, but also in the business, sales and finance areas.

A big challenge is to convince investors in Europe that our business model needs a longer time than others to reach expected revenue targets. Unlike in the US, European investors are more risk-averse and search for faster revenue models.

We have been awarded multiple times, not only for our idea but also for our technology, business model and commitment to the environment. We have been recognized by the Repsol Foundation, the UN, European Commission, Green Building Council Spain, Eco-Emprendedor XXI, Volkswagen Think Blue and the European Business Angel Network.

On the bright side, I can say that the focus on the market and real client needs has helped us to pivot – by quickly adapting our initial value proposal to serve the industry's real needs and expectations – which has been the best way to success in commercial contracts and deals.