Algae play a crucial role in the coastal ecosystem by protecting coasts from erosion and removing excess nutrients from the water. However, the growing global demand for seaweed challenges the sustainability of its farming and harvesting. According to the European Community, several species of algae are gradually disappearing from southern areas where they have usually grown.

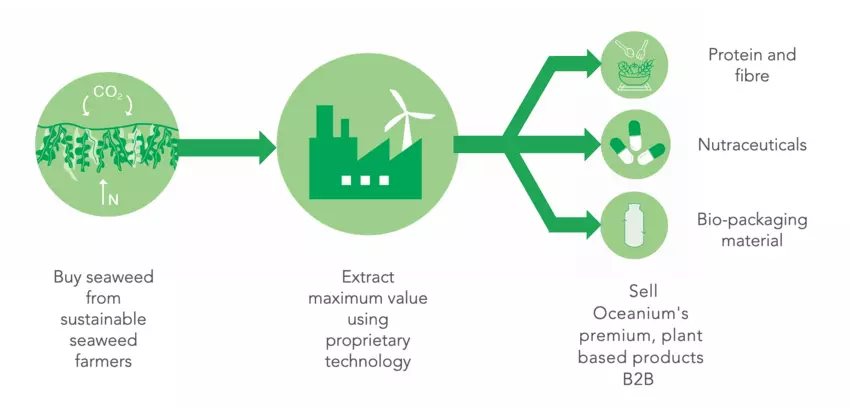

Scottish startup Oceanium aims to sustainably source and integrate seaweed across supply chains in a way that mitigates environmental challenges. It has developed a proprietary biorefinery and processing model to create seaweed-based products for use as ingredients across industry verticals.

Oceanium sources its raw material locally by partnering with sustainable seaweed farmers. “We aim to contribute towards economic development and job creation in coastal communities by supporting small-scale farmers when purchasing seaweed (…) and helping enable the nascent sustainable seaweed farming industry,” Oceanium’s CEO and co-founder Karen Scofield Seal said.

Last November, Oceanium was one of 85 green startups selected by the UK government to access over £9m in grants. It recently received £2m seed funding to scale production and accelerate commercialization. The round was led by the impact investment fund Green Angel Syndicate with the participation of the WWF, an ultra-high net worth family office and a group of angel investors from Europe, the UK and the US.

“The caliber of investors in this round of funding highlights the opportunity and obligation we have to create a market for sustainably farmed seaweed and drive systemic change by providing regenerative food and material sources,” Scofield Seal said.

Multiple uses

With a background in business development, brand-building and marketing, Scofield Seal was looking to start an impact business that would turn seaweed into sustainable packaging when she met CTO and co-founder Charlie Bavington, holder of a PhD in biochemistry with over 20 years of experience in developing and commercializing marine-based products.

Oceanium was one of 85 green startups selected by the UK government to access over £9m in grants

Bavington confirmed the feasibility of Scofield Seal’s project, and they soon started to work together on Oceanium’s biorefinery business model, also capitalizing on seaweed’s nutritional ingredients.

Oceanium has three product lines. OCEAN HEALTH is directed to the food segment to tackle the increasing demand for plant-based ingredients providing a range of water-soluble nutritional constituents such as fibers and proteins. The second product, called OCEAN ACTIVES, includes bioactive nutraceuticals and cosmetic components. It is expected to be launched at the end of 2021.

The company is also working on the early iterations of its OCEAN WARE prototype, a bio-material in film and board formats for biodegradable packaging. Since 2019, Oceanium has been collaborating with Mara Seaweed, a pioneer in sustainably harvesting and processing seaweed. The two companies are jointly developing bio-materials and aim to start commercial trials in the near future with fully biodegradable seaweed-based packaging.

“When I look at the supply chain, the demand is off the charts for bio-packaging,” Oceanium’s COO Andy Wilkinson said. The company aims to integrate its product in the packaging industry as a compostable alternative to plastic.

As of December 2020, Oceanium’s biorefinery technology processed about eight tons of wet seaweed. It plans to achieve 45 tons by the end of 2021 and aims to reach 5,000 tons by 2024 to move closer towards its goal to “kelp the world.”

Closing the protein gap, sustainably

Asia leads the chart in seaweed production, whereas Europe lags, contributing to only 1% of the total global output of an estimated 30m tons per year. However, the demand for seaweed has grown over the years, primarily due to increased awareness of the environmental cost of meat production. “In the UK, people are converting to become vegans more rapidly than anywhere else,” Wilkinson said.

Europe has a high reliance on protein imports, with 70% of protein-based crops used in livestock feed and plant-based foods being imported. According to Scofield, Seal seaweed can help close the protein gap in the more immediate term.

Besides helping to close the protein gap, "seaweed farming also protects the seabed from commercial fishing and other harmful practices and creates a marine sanctuary for sea life,” Scofield Sea said. “[It] also has other immensely positive environmental impacts, as it does not require cleared land, freshwater, insecticide or fertilizer.”

“Our seaweed-based materials can replace resource-intensive food and feedstocks, which often contribute to deforestation. In addition, seaweed farms encourage responsible coastal management and create marine protected areas for sea life,” she added.

Oceanium conducts life-cycle analysis on its process and products to track and report its environmental impact as it scales. “We are liaising with organizations like Seaweed for Europe and the UN Global Compact Seaweed Manifesto to help quantify this carbon absorption and to ensure this exciting new industry grows in a sustainable and managed fashion,” Scofield Seal said.