After finding out that his baby daughter Sophie was severely allergic to shrimp, Eugene Wang, a serial entrepreneur in the vegetarian food sector, started Sophie’s Kitchen in 2010 in the US to “find ways for people to get nutrients from the ocean without using animals,” he later recalled. His company started using peas and potatoes as ingredients and now offers a wide range of plant-based seafood, including shrimp, scallops, crab meat and smoked salmon.

While running Sophie’s Kitchen, Wang was regularly asked whether its plant-based seafood products were nutritionally equivalent to the real stuff. He answered no every time. Although soybean, pea and wheat are still among the mainstream ingredients used to create plant-based alternative protein, they have their own limitations. As Marie-Christin Baun of The German Institute of Food Technology pointed out, “certain essential amino acids are often limited in plant proteins.”

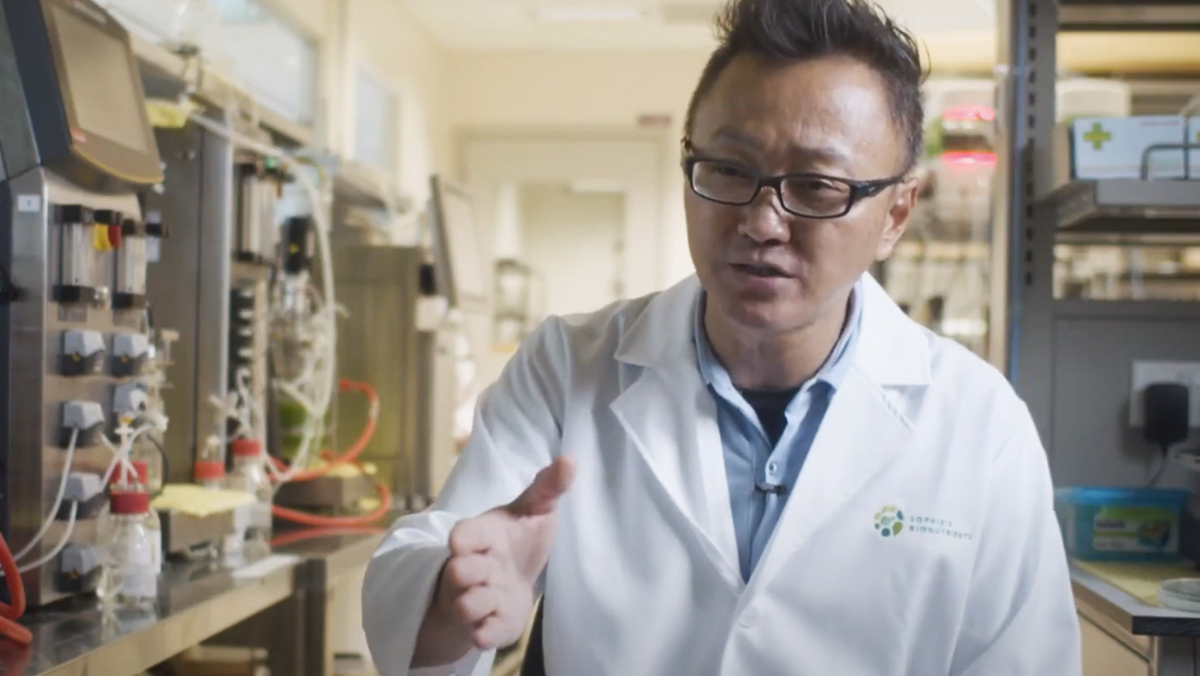

Inspired by how fish in the ocean get their nutrients from algae, in 2013, Wang set his sight on microalgae. In 2019, he spun off a microalgae research unit in Singapore called Sophie’s Bionutrients. He himself also stepped back from Sophie’s Kitchen to work full-time on microalgae which he has described as the “superfood of the future.”

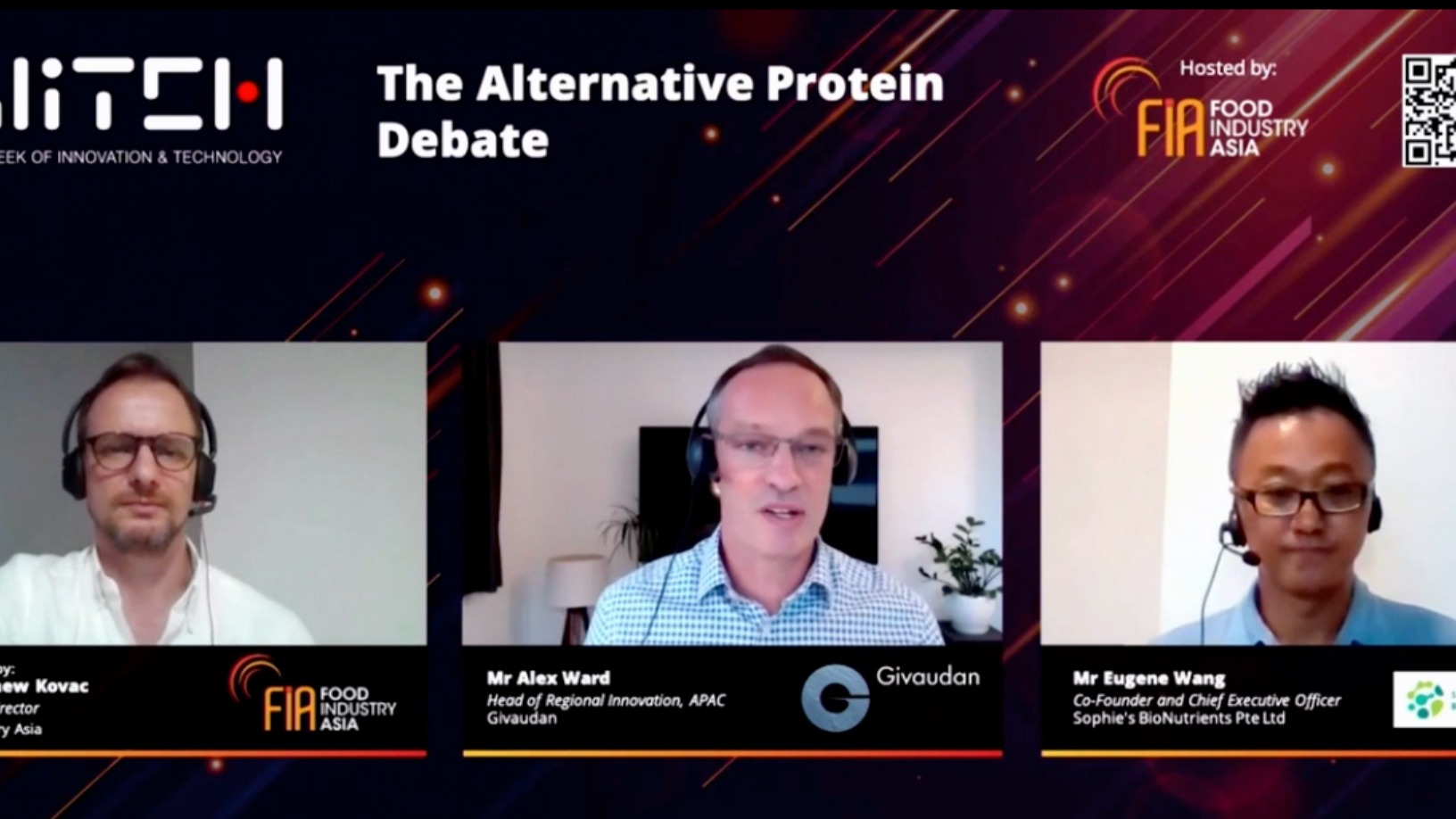

In 2019, Sophie’s Bionutrients won the S$1m grand prize from Temasek Foundation at The Liveability Challenge, an annual event to search for ideas from across the world to make Southeast Asia's cities more liveable and resilient. This May, it won the pitching competition at MassChallenge Switzerland's Sustainable Food Systems Challenge. In 2017, Wang was the grand winner at the Slingshot@Switch 2017 competition in Singapore.

The startup reportedly raised $1.17m seed investment from Denis Asia Pacific, SEEDS Capital and Temasek last year. Wang also disclosed recently that Sophie’s Bionutrients is trying to raise $10m in a new funding round. “The biggest cost is in obtaining the land and fermentation tanks to scale production,” he explained.

Sophie’s Bionutrients has chosen Singapore as its initial production base and is building a 464 sqm production facility that will house industry-scale bioreactors with capacities of between 2,000 and 20,000 liters, producing up to 10 tonnes of protein flour monthly.

Magic protein flour

According to the company, its microalgae-based flour can take on unlimited forms, textures or colors and thus can be used to make almost any alternative protein product. The microalgae are grown in bioreactor tanks, with no photosynthesis process, giving the protein flour a very light color that can be easily removed. Also, because there are no bacteria inside the tanks, “the smell of our microalgae is very light and pleasant,” Wang said.

The protein flour is sold to food companies at about $30 per kg. Wang hopes this price will be brought down to $2 within 5–10 years as production scales up, making it possible to feed developing countries.

So far, the flour has already been supplied to local food manufacturer Ha Li Fa to make crab cake, which is awaiting halal certification and is expected to be sold in Singapore later this year. In April, Sophie’s Bionutrients unveiled its plant-based burger patties made from microalgae, which the company claimed is the first of its kind in the world.

According to the company, its plant-based burger patty has up to two times more protein than beef or cheap fish. Weighing around 60g, each patty contains 25g of proteins – comprising all nine essential amino acids. This is 10% higher than the total amount of protein content found in many types of cooked fish.

Earlier this month, the company launched its plant-based milk alternative, also made with its microalgae flour. The milk does not taste like cow’s milk and has a texture similar to nut-based milk. Wang said it’s up to food manufacturers to add flavorings and tweak the texture by adding fat to make it closer to dairy milk.

Other products in the pipeline include protein crackers which will be sold to plant-based burger makers by 2022. “We are constantly on the lookout for partners who can help us develop new and exciting products to showcase the capability and versatility of microalgae flour,” Wang said.

Urban farm-friendly

The microalgae at Sophie’s Bionutrients are grown in bioreactor tanks in its lab, a protected and controlled environment compared to conventional sunshine ponds. It does not use herbicides, fertilizers or antibiotics. “Our microalgae are fed with industrial food waste like spent grains, okara and molasses,” Wang said. “This is for a circular economy and reduced costs.”

Protein can be extracted from the harvested algae and converted into edible protein flour within three days. “Our production cycle is fast, lasting only three to ten days, versus 45–65 days for soy and 1.5 years for beef,” Wang explained. Reduced cultivation time translates to less consumption of water and energy. According to Wang, 90% of the small volumes of water used in production can be recycled.

The company's processes also allow for output 10 times higher than conventional microalgae farming practices. "To produce a tonne of soy protein, you need five hectares of land. For us, it's about 0.02 hectare," COO Barnabas Chan said.

With no need for much land space, it is possible to locate Sophie’s Bionutrients system in urban areas. The company is looking to expand to countries where the land costs are lower, and there is a more readily available source of feedstock to grow the microalgae, Wang said.