Tapping the quantum physics theory of the universe being made up of “strings of energy” created by billions of atoms in motion, Lithuanian cleantech energy startup Viezo has developed a vibration energy harvesting technology to capture and collect the small amounts of energy created through vibrations, converting them into electrical energy.

The Viezo founding team was working with Kaunas University of Technology to explore creating energy from raindrops when they discovered that vibrations could be used to produce sufficient energy to operate any type of sensors and low-powered IoT devices in a fairly inexpensive and sustainable way.

“We wanted to do something within the renewable energy sector,” Viezo CEO and co-founder Donat Ponamariov said in a recent interview with CompassList. “They [Kaunas University] told us about the problem of wireless sensors lacking energy, and that the materials we were researching could be used to develop vibration energy harvesting technology.”

Founded in 2018, Viezo started to experiment with the use of vibration energy harvesting to power sensors for railway maintenance. The team went on to further refine its technology and adapted it for other industrial IoT applications.

“We are not talking in kilowatts, but in microwatts as we focus on small sensors only; not charging phones and computers,” said Ponamariov. “Right now, we are focusing mostly on the railway industry where there are a lot of vibrations, and there is a huge need for those sensors.”

Currently, Viezo’s technology can extend the battery life of sensors by up to three times longer than those powered by conventional batteries, which typically last for up to five years and require maintenance. Besides, batteries aren’t cheap: prices range from $80 to $500 per replacement, with labor costs exceeding the price of a new sensor. Viezo’s proprietary technology, dubbed PolyFilm, can cut the costs by nearly 60%, according to the company.

Scaling through outsourcing production

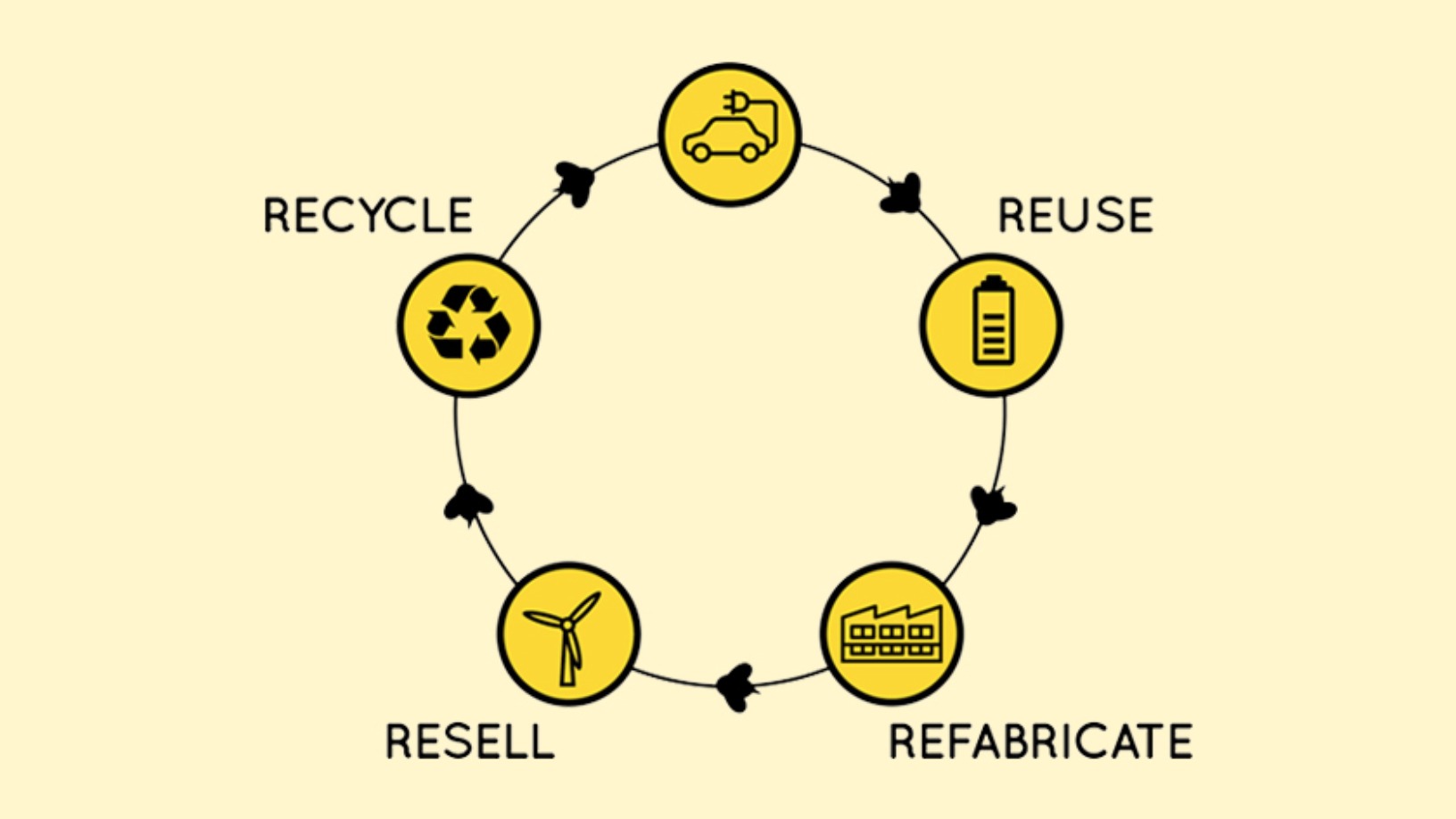

The cleantech startup aims to produce its energy harvesting devices commercially as substitutes for conventional batteries in a market where sales are expected to grow to $300bn in 2030.

Pending an international PCT patent, PolyFilm was developed by Ponamariov with co-founders Vytautas Jaškevičius and Donatas Darkšas as the company’s chief business development officer and CTO, respectively.

“Vytautas and I were previously working in the same company, we needed to find the CTO that we met via LinkedIn,” Ponamariov said, “it took approximately two years to make this happen.” An electronics engineer, CTO Darkšas is passionate about smart home technology, IoT, machine learning and artificial intelligence.

To make the power conversion, PolyFilm deploys a piezoelectric (PVDF) material to make eco-friendly polymers. The PVDF is then assembled in a lead-free cantilever structure: one side is fixed and the other one is loosened to allow the vibrations to generate electricity.

“We are using technologies that are already known and we have proprietary ownership of several [other] materials that, once put under a physical stress, generate a voltage output,” he added.

The extra power is stored in a supercapacitor that runs the sensors whenever vibrations are not present, hence bypassing the risk of power shortages. The whole hardware manufacturing is done in-house, with the PVDF material sourced from suppliers in China and the US.

“We haven't scaled yet to produce in big volumes, but in the future we are planning to outsource the production,” Ponamariov said.

Viezo’s products currently include Powerail, a self-sustainable monitoring system for railway maintenance, and SONORA, an analogous wireless sensor series that provide autonomous sensors for diverse industries like manufacturing, mining, oil and gas. The startup has also developed a vibration energy harvester, named Strider, and its complementary vibration data logger, Terra-X, to assess the feasibility and efficiency for various applications.

Seed funding to scale-up

To date, the company has piloted its technology in the smart tools and construction industry and in the monitoring of industrial pumps and generators. In the pipeline are also new proof of concepts for the generators and mining industries.

“There’s still a long way to go since it’s quite a sophisticated technology,” Ponamariov said.

In July 2021, Viezo was selected to join TechFounders’ 20-week accelerator program in Munich. “We also passed through some incubation programs, but until now, TechFounders is by far the best one,” he added.

In 2020, the startup closed the year with a turnover of €130,000, mostly from paid pilot runs. Commercial trials and tests are planned for early 2022, focusing on Powerail sales in the European markets.

So far, Viezo has had financing of €60,000 from a European Institute of Innovation & Technology grant and €180,000 from The Lithuanian Business Angel Network, Ponamariov said.

The startup is also in the midst of securing seed funding from a group of local angel investors and international VCs.

“We are just dealing within the documents and everything else,” he said. “We are expecting to close it within the next months.” The capital will be mostly used to prepare for the commercial launch of PolyFilm in 2022, and to boost the team with more key personnel.

“In the next eight months, we are also looking to expand the team with approximately 12 people,” he said. “We'll be hiring engineers to develop the Powerail, which is by far the most important thing, and also to expand the business development team to sell it properly.”